First take

25.08.2015

Recipes need to be talked through and implemented with precision

The current “menu” at Salzgitter Flachstahl includes around 450 different grades of steel, with more to come as the trend towards differentiation grows stronger

Take a handful of manganese, some silicon and a pinch of niobium, stir evenly into the molten crude steel – and the mixture is ready to serve: The resulting steel is of an outstanding quality that even the most demanding critic could not fault. Perhaps in reality it is not quite so simple, but quality steel has much in common with the dishes that top chefs serve to their guests. Superb cuts of meat or fish, enhanced with aromatic herbs and spices.

“Our customers within the Group are the hot mill in Salzgitter and the plate mills in Ilsenburg and Mülheim”

The “primordial soup” is brewed in the blast furnace, where iron ore along with coke and other additives is smelted to produce hot metal. This in turn is brought to the steelworks where it is turned into crude steel (see panel). It is at the secondary metallurgy stage that the “spices” are added: individual alloying elements such as niobium, manganese or nickel.

Of course the steelworks’ “kitchen” is far removed from the gleaming stainless steel array in a luxury restaurant. No polished copper pans here, but mighty converters and ladles in which the “dishes” simmer, up to 220 tons at a time. Cooking temperatures here are 1,600 to 1,700 °C rather than 70 °C – and the fire-proof coats worn by the “steel cooks” are far tougher than the chef ’s kitchen whites. Yet both offer “haute cuisine” for discerning customers.

One of the “sous chefs” at the Salzgitter Flachstahl GmbH (SZFG) steelworks is Christian Schlüter, head of secondary metallurgy. One of the tasks that falls to him and his team is to ensure that the “cooked” steel exactly corresponds with the recipes determined in advance to meet customer requirements: “Our customers within the Group are primarily the hot mill in Salzgitter and the plate mills in Ilsenburg and Mülheim. They require us to produce precisely the desired input material which their customers in turn will use to manufacture automobiles, washing machines, pipelines, wind turbine towers or even ships.”

The type of alloying ingredients, added in precisely calculated quantities, are decisive in achieving the steel characteristics that customers require. Thomas Müller, head of the steelworks at SZFG, explains: “Steel is constantly being developed, and with around 2,500 standardized grades to use as a basis, the European steel industry now produces a whole range of customized qualities. Each year about 100 of the standard grades are adapted to meet increasingly specific demand. And of course entirely new grades are being developed all the time.”

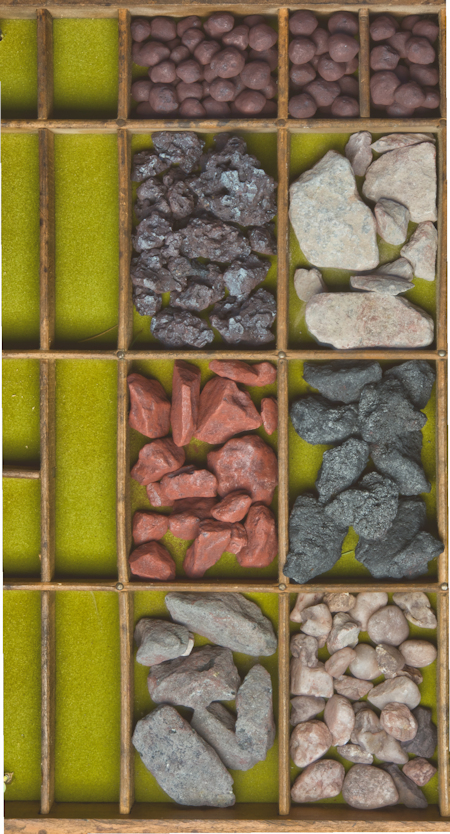

The current Salzgitter Flachstahl “menu” comprises around 450 different grades of steel. “This is not a fixed list, of course we also accommodate special requests,” says Jens Pischke, head of process engineering development. And necessarily so, as the trend towards differentiation grows stronger. The most frequently used alloying elements are manganese, aluminum, silicon and carbon, but molybdenum, chromium, nickel, vanadium, titanium, niobium, boron and copper also feature. “We currently have 20 alloying ingredients,” Pischke adds. The most expensive is ferro-niobium, of which there are only three producers worldwide.

Secondary metallurgy operating engineer Arne Vollmers continues: “The alloying ingredients are mainly added to the crude steel from their containers in our secondary metallurgical treatment shop plant. Argon gas is introduced into the 1,600 °C melt through fire-proof purge blocks in the base of the ladle, and this ensures that everything is thoroughly “mixed” – the purge block is our equivalent of a spoon.” Once the “steel soup” is ready – which takes around 60 minutes – samples are taken to check whether a homogeneous distribution of ingredients has been achieved. Provided that all of the other parameters have also been met, the steel is transported to one of the four continuous casting lines poured into the mould and casted to a strand, that is finally cut to length into slabs. The main consumer within the Group is the hot mill which receives around 75 % of output for rolling into coil. But that is another story …

To increase the quality and capacity of its secondary metallurgy, Salzgitter AG recently placed an order for the construction of an RH vacuum treatment plant (RH = Ruhrstahl-Heraeus). Thomas Müller explains: “With this plant we should be able to meet customers’ requirements for extra-deep desulfurized, decarburized and hydrogen-degassed steels as well as steels with the highest level of purity. The preliminary works began in June, and the plant is due to enter Service.

“It’s important to work with suppliers on an equal footing”

The Procurement department at SZFG on procuring raw materials

The raw materials requirements for steel production are sizeable. This is reflected in the roughly € 1.3 billion costs at Salzgitter Flachstahl GmbH (SZFG): STIL spoke to Michael Reuber, Procurement Director, and Lars Bartram, Head of Raw Materials Procurement, about the multifaceted nature of their roles.

STIL: Which factors are decisive in where and from which providers you buy a specific product?

Michael Reuber: For our long-term procurements, we pay particular attention to supply reliability in addition to the price and quality of the goods. In other words, it is important that the provider can guarantee constant delivery of the required volumes in the agreed quality. After all, ore and coal cannot be interchanged at will. Just like other iron and steel works, we have developed a very specific “bouquet” based on the requirements of our internal customers. This is also dependent on how the blast furnace is “fired”, in other words the ratios of pellets, lumps and fines. We have to procure the right volumes for this mix accordingly. One prime example for a long-standing supplier that fulfils all of these conditions is the Swedish company LKAB. We have been procuring pellets from them for decades, making up around 40 % of the required total ore volume.

STIL: How do you ensure that you always get the best product in terms of price and quality?

Lars Bartram: As good traders, we always aim for the best value for money. On the one hand, we have our system suppliers like LKAB, with whom we conduct regular price discussions. For more short-term procurements, we use the usual methods: We announced the required volumes, enquire with suppliers and do business on the spot market. There, very rapid decisions are sometimes required. In this case, the short decision-making processes within SZFG and the group are a big help. The joint meetings with the technical management are also important. We already explain in advance what effects new systems will have on our procurement behavior. Based on this we buy new types of coal for the pulverized coal injection plant which entered service this year. On top of that, we check the quality of the goods on a regular basis. Michael Reuber: Another brief word about our system suppliers. It’s important to work with suppliers on an equal footing. LKAB is a prime example. It produces 26 million tons of ore every year, while the world market leader Vale produces 340 million tons. When it comes to our procurement volume of 2.5 million tons of pellets, the Swedes are operating on a more similar scale to our own.

STIL: How many different items are on your regular “shopping list”?

Lars Bartram: In the raw materials field it is roughly 100. This notably includes 6 types of ore, 8 different types of coal, as well as 15 types of flux and alloying element groups. In terms of volume, lime is the most important flux, and we require some 1 million tons of it a year. By the way, our lime supplier FELS is located just around the corner in Goslar, while the lime is mined in the Harz region. Michael Reuber: In total, our “shopping list” contains well over 100,000 items – from pencils to large plant equipment.

STIL: How many employees are in your department and how high is your annual budget? Michael Reuber: In total, 75 colleagues are employed in Procurement at SZFG, of which ten work in the Raw Materials Procurement department. Our procurement volume in 2014 amounted to almost € 2 billion, of which €1.3 billion was attributable to raw materials.

STIL: Do you just procure goods for SZFG or for the entire group?

Michael Reuber: Some goods and services are centrally procured by Salzgitter AG . This includes energy procurement as well as travel and fleet management (business travel/company vehicles). For the groupwide pooling of requirements and coordination of procurement processes, we use group procurement coordination. As part of our “Salzgitter AG 2015” streamlining program, the procurement mandate was extended. We have already been operating on this basis for years for our sister companies PTG in Peine and MGR in Salzgitter. In the last twelve months, we have also taken over procurement for ILG in Ilsenburg, MG B in Mülheim and SZMF in Duisburg/ Salzgitter. Further mandates are pending implementation.

STIL: How has your approach to work as well as the markets and challenges changed in the last ten years – in the case of ore, for instance?

Lars Bartram: Things have changed substantially. Until 2009, annual price agreements were the norm, which made long-term cost estimates possible. Nowadays we have quarterly prices, which are also only set at the end of the delivery quarter. This means that a great deal more coordination is called for, in connection with a high number of additional aspects due to the highly volatile markets. This has also placed more exacting requirements on our staff.

STIL: What is the most exciting product that you procure?

Lars Bartram: Coal, without question. Until 1995, coal was exclusively sourced in Germany. Since 2005, however, we buy the entire volume from abroad – from Australia, Canada or the USA. Restructuring the system was a real challenge.

STIL: Can you describe how contacts with large suppliers work?

Michael Reuber: It is the same as in all industries – personal contact is important. You have to see each other at least once a year, and this includes visiting customers on site in raw materials procurement, as well as almost daily telephone conversations with us or our employees. Ideally, you can establish a cooperative, resilient relationship, which allows any emerging problems to be solved quickly.

STIL: What makes a good procurement department?

Michael Reuber: In addition to outstanding market knowledge and good teamwork as well as close coordination with our technical colleagues – our customers in the production companies – the commitment of all employees is worth emphasizing. In the world of raw materials, the sun no longer sets, as some suppliers are based in Australia, while others are in Alaska - which means that you sometimes have to make calls outside of the usual business hours.

They are grey, inconspicuous and measure just ten millimeters in diameter, but they truly pack a punch – pellets from Kiruna in Sweden. These pellets boast an outstanding iron content of 68 %. By importing some 3 million tons every year, Salzgitter Flachstahl GmbH covers almost 50 % of its overall demand with iron ore from Sweden, sourcing the remainder from mines in Canada, South Africa and Brazil, among others.

The Kiruna iron ore mine is regarded as the world’s largest. Around 26 million tons of ore are extracted here and in Malmberget every year. As the deposits almost entirely consist of magnetite and apatite, they influence the magnetic field of the Earth – an effect that is even measurable from space. This material has another priceless advantage: Magnetite ore oxidizes to produce hematite during the energy-intensive production of pellets, generating huge amounts of heat in the process.

I always wanted to drive one of these huge trucks after my dad showed them to me once,” says Felicia Uusitalo – and she has realized her childhood dream. For the last two years the petite Swede has driven a mighty Komatsu HD 785-7, with specifications that speak for themselves: 1200 horsepower, 100 tons payload, five meters high, seven meters wide and eleven meters long. With her delicate hands, Felicia steers this monster through the Svappavaara pit with a load of enormous rocks on board. After taking her driving test and one week’s accompanied driving, Felicia was allowed to take the wheel alone. Did she feel much fear? “Fear, no; respect, yes. Once you get used to the size of these trucks, though, they’re quite easy to drive,” she says. “It’s only in winter that you have to be really careful because of the ice and snow.” Each driver in Svappavaara is responsible for his or her own truck, and for the extensive safety check that has to be carried out before every shift.

21-year-old Felicia loves not only her unusual job, but also her unconventional home. “My main hobby is snowmobiling with my boyfriend,” she says, enthusing about this year’s snow conditions which allowed her to continue going on trips until the end of June. Her favorite season is winter, despite the two months of perpetual darkness: “Those weeks have their own special charm - with the Northern Lights, for example.” At home, Felicia also likes things on the extra-large side: her pets are two Great Danes …